We specialize in handling with robot guides

and in processing control

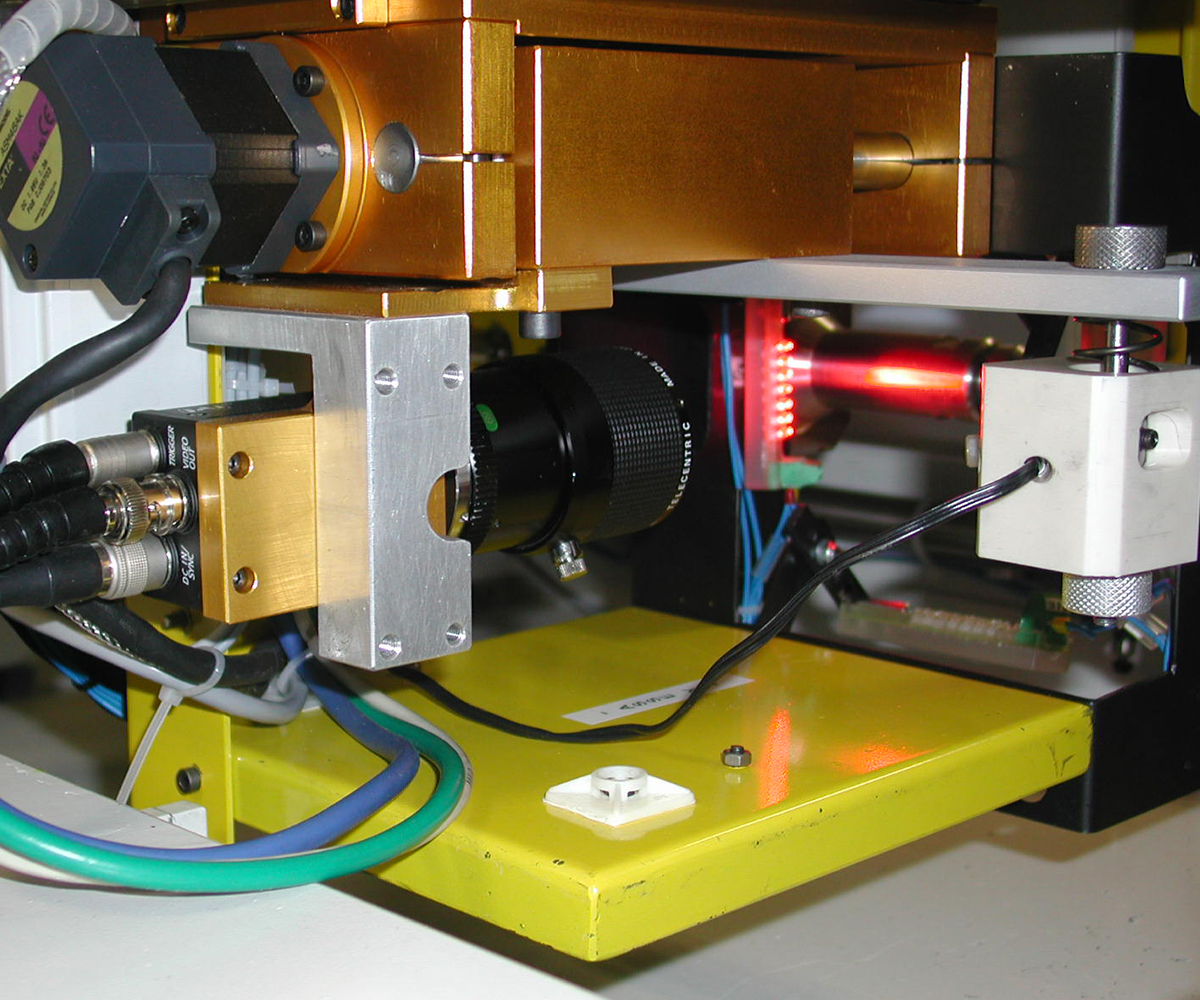

Vision Systems

In the field of mechanical components machining, such as gears, brakes, wheels, etc. vision systems are used for the semifinished components handling (guides robot) or, more generally, to ensure the quality of the themselves pieces.

From the point of view of industrial vision, it is necessary to be able to operate with multiple surfaces types o, both for the materials variety and for manufacturing (rough, polished, painted …).