System Functions

his vision system, designed for the automotive industry, is able to perform various controls in a critical point of the wheels production line.

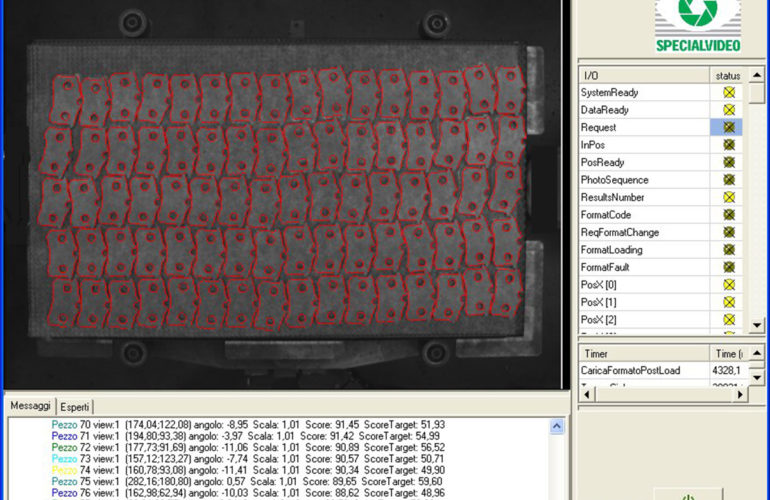

Many wheel rims models are printed from the upstream presses conveyed with a single line to the balancing machine and the pieces finishing area. At this line point it is necessary to distinguish between the various wheel rims types in order to properly execute the successive processing stages . It ‘s also important to identify the hole valve position if it is empty or if there is a suitable object added to simulate the valve weight.

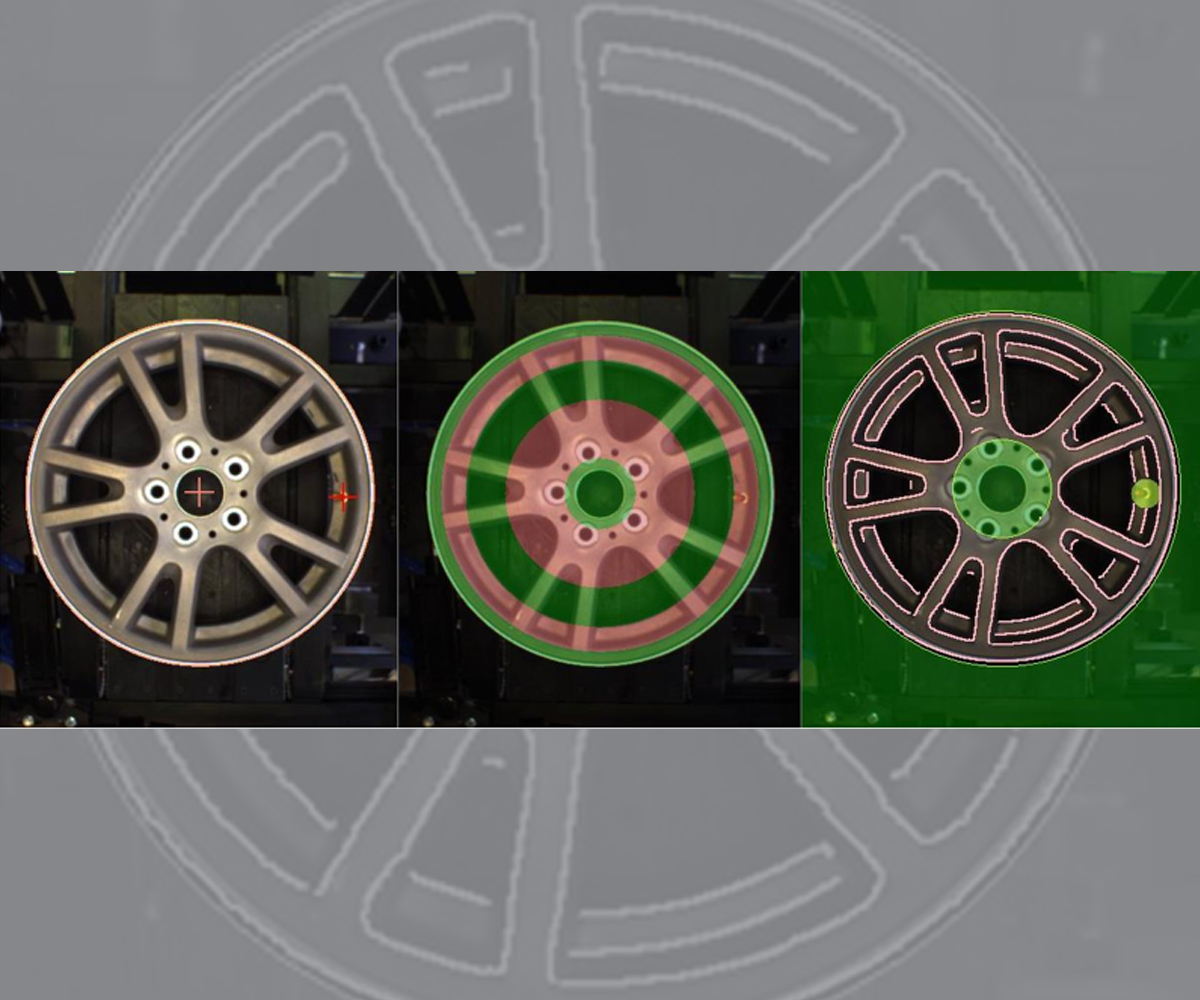

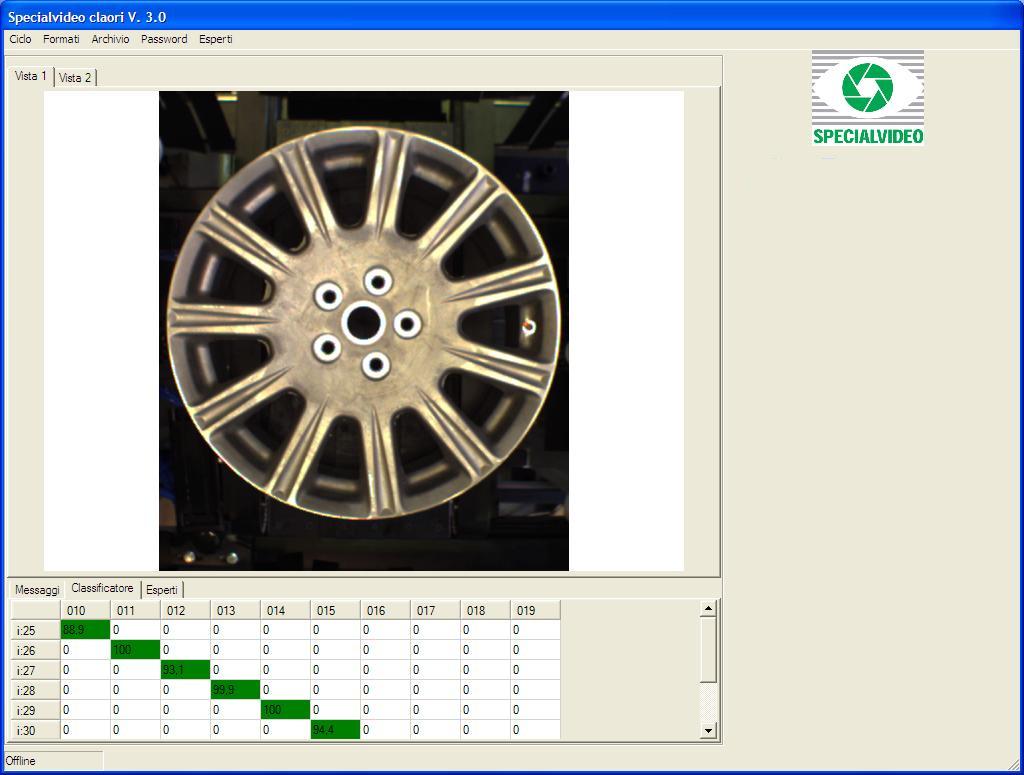

The vision system determines the wheel type according to the front wheel height, diameter, offset and design. The design recognition takes place thanks to a geometric pattern matching able to identify the piecemodel in a few seconds. The software then communicates the rim type and the orientation to the brushing and balancers machines.

Knowing the location and the valve simulator type (if present), it is necessary to properly perform the wheel adjustment and balancing verification. Different weights correspond to different colors simulators valve. The vision system should therefore apply the color recognition to identify the simulator weight and send it to the balancing machine.

The algorithms

The algorithms developed by Specialvideo for this application are designed for multiple rims models. An easy memorization phase guides the operator to learning new rims patterns. If there was a significant stored wheels amount, it is possible the models identification produced without deleting the remaining ones from the database the.The remote assistance service also allows you to significantly reduce the technical intervention time and costs.

System Description

The data on height, diameter and offset of the rim are calculated from the other line equipment and provided to the vision system. The height calculation is based on a Datalogic barrier of photocells. Pattern matching is instead calculated on a captured image by the vision system camera.

Depending on the specific requirements it is possible to have a color system or a gray levels one, while the illuminator can be constituted by LED or flash.

The results can be notified to the host system or to the robot. In general, this vision system can be used both for the verification of the final product and to manage the subsequent processing stages , such as the balancing control or the defects elimination by brushing machines.

The wheel belonging to a given model is based on a similarity score, which is visible in the interface. The score acceptance parameters can be edited by experienced operator.