We inform you that our offices will be closed for holidays on 25th and 26th April 2024.

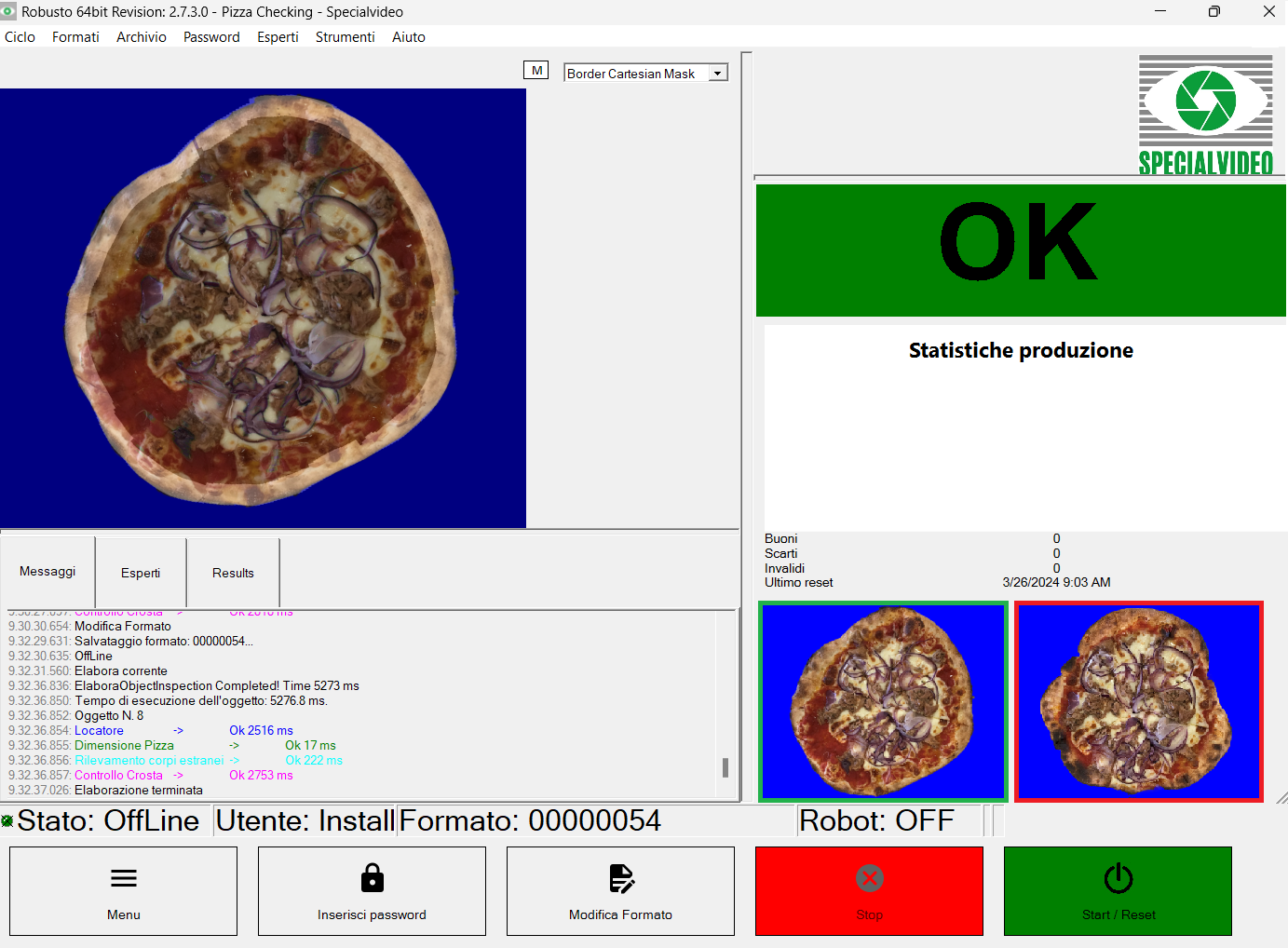

Specialvideo presents a Deep Learning quality control for pizzas, that inspects the toppings by returning the count and extent of ingredients classified by type, as well as performing classic checks such as shape integrity, color conformity, and detection of possible blue pollutants.

The application made for pizzas is suitable for other food products that have the ingredients to be checked visibly arranged, e.g., ready-made salad and pasta dishes.

To learn about the system, we invite you to read the case history and contact us for more information.

Our passion for the most innovative technologies is expressed since the first years of our activity.

Already in the early nineties, Specialvideo realized, in addition to 2D systems:

- 3D systems, with laser projectors designed ad hoc, to search for the weld bead of pipes;

- systems with self-learning statistics, the techniques that were then at the center of artificial intelligence, for the quality control of blisters and food products;

- proprietary algorithms for finding the valve hole notch in raw castings of light alloy wheels, still in high performance production;

- calibrated (precision) measuring systems for the control of keys, also adopting telecentric optics.

Just one year after its foundation, in 1994, Specialvideo implemented the first robot guidance with conveyor tracking, and expanded the range of technologies with the introduction of linear cameras and color cameras.

In the same years Specialvideo adopted LED lights, which were not yet a standard and therefore required a special card for adjustment and synchronization with the cameras, which were analogue at the time. In the late nineties, the first digital cameras arrived on the market, which Specialvideo adopted for a rapid evolution of its vision systems.

In 2023, Specialvideo has found the strategic partner for the development of the company: G.D S.p.A., a company of Coesia group, which participates with a minority stake.

A rapid succession of new technologies, integrated into our systems year after year, has led us to celebrate 30 years of activity with cutting-edge vision systems.

We thank our team of colleagues, customers, suppliers and partners who make all this possible.

We wish you a happy summer and inform you that our offices will be closed from August 14th to 20th 2023.

The mass-produced “smart camera” vision systems can sometimes not have the solutions to specific automation needs that industries face to distinguish themselves in their sector. Then you can choose a vision system designed ad hoc by Specialvideo, made with equipment commensurate with its production lines and equipped with software developed in accordance with its production processes.

The project starts from a preliminary study in the laboratory carried out on the samples supplied by the customer, with attention to the specific performance needs, integration into the production line, and possible incorporation into Industry 4.0 projects.

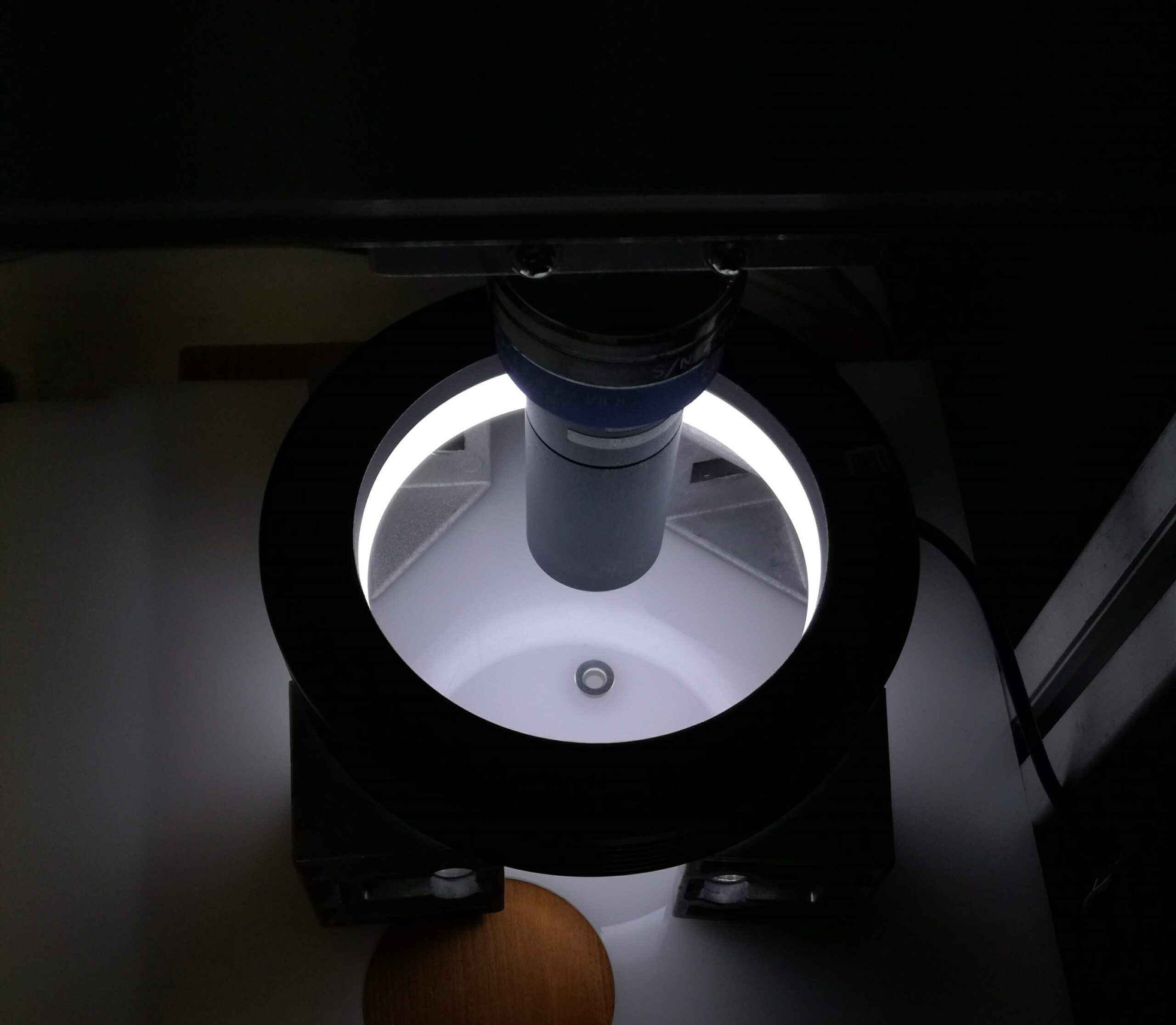

In the creation of an ad hoc designed vision system, the cameras, the optics, and the light sources are specially selected to integrate into the customer’s production line, respecting the spaces of the pre-existing mechanical parts and acquiring images with specially designed lighting. The artificial vision software is developed to achieve the required performance and optimized to process within the normal production process times.

In the field of industrial quality control, ultra-high resolution images are characteristics of spot checks carried out with optical instruments by specialized operators.

Specialvideo offers the automation of visual inspection at very high resolutions, through::

- the selection of cameras combined with appropriate high quality optics

- the study of lighting and background, to enhance the details of the product and its defects

- the design of the motion scan to inspect 100% of the product surface

- the design and development of the application code, with classic Computer Vision and Deep Learning, also combined in hybrid solutions based on the strengths of both types of software: reliability, precision and generalization.

The total size of the product and the cycle time, selected by the customer, will be the basis of the design of the scanner, which can be composed of a group of several cameras, which can be matrix o linear cameras depending on the type of inspection.

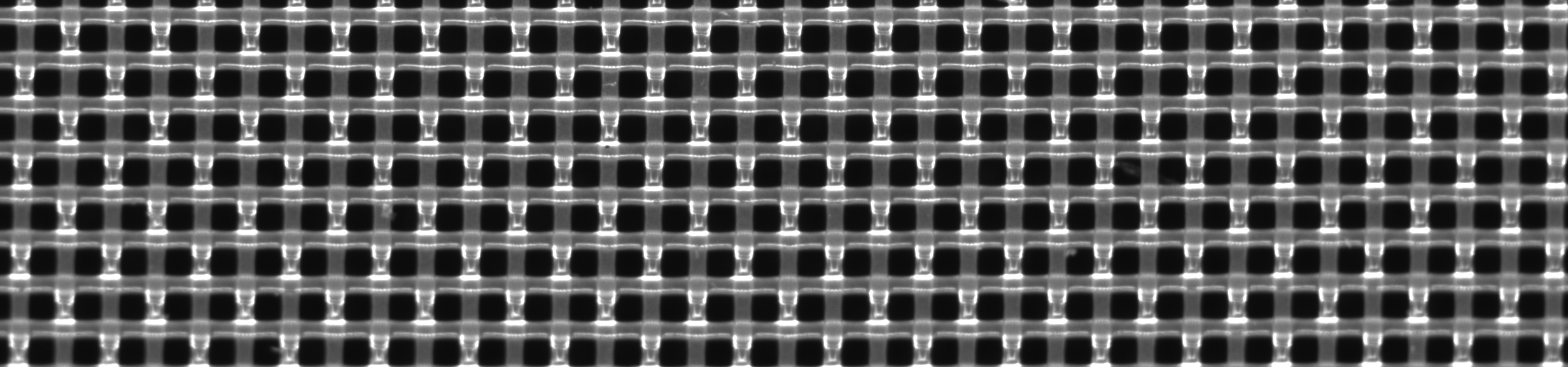

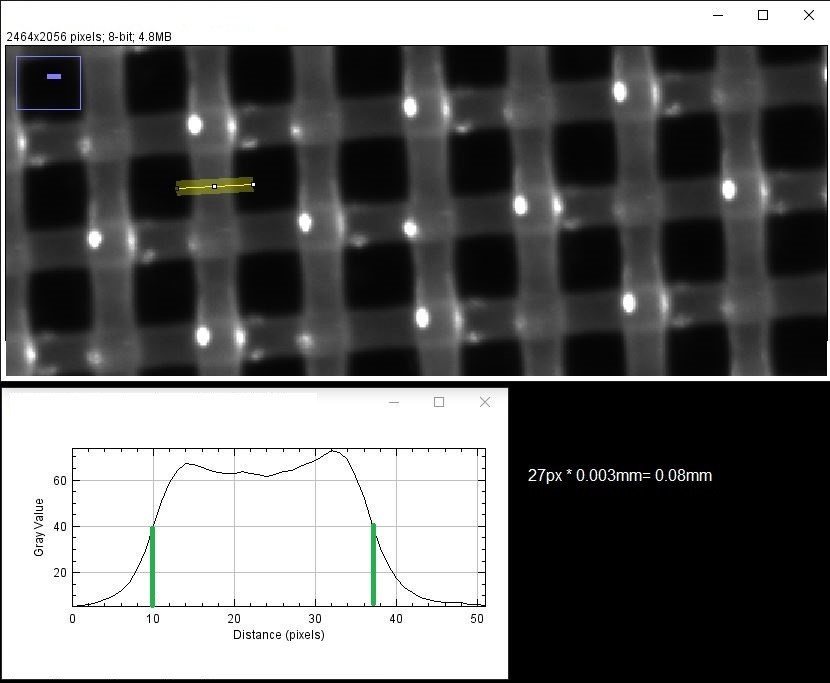

The following image, deliberately enlarged to allow to see the resolution of 3 microns per pixel, shows a technical fabric for filtering, with a 80 micron thick thread.

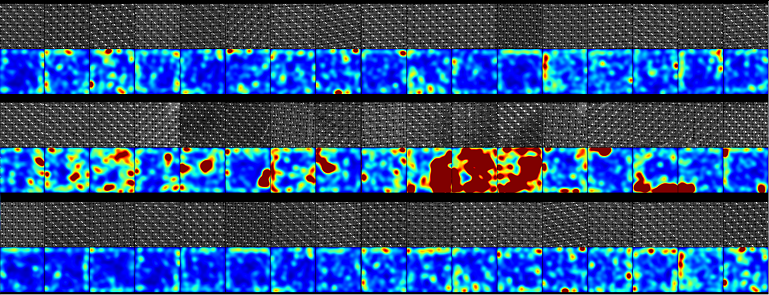

In the following figure, a series of images are analyzed by an Anomaly Detection Neural Network which depicts the output in blue for portions recognized as compliant and in red for non-compliant portions: