System functions

Boxes Completeness Check

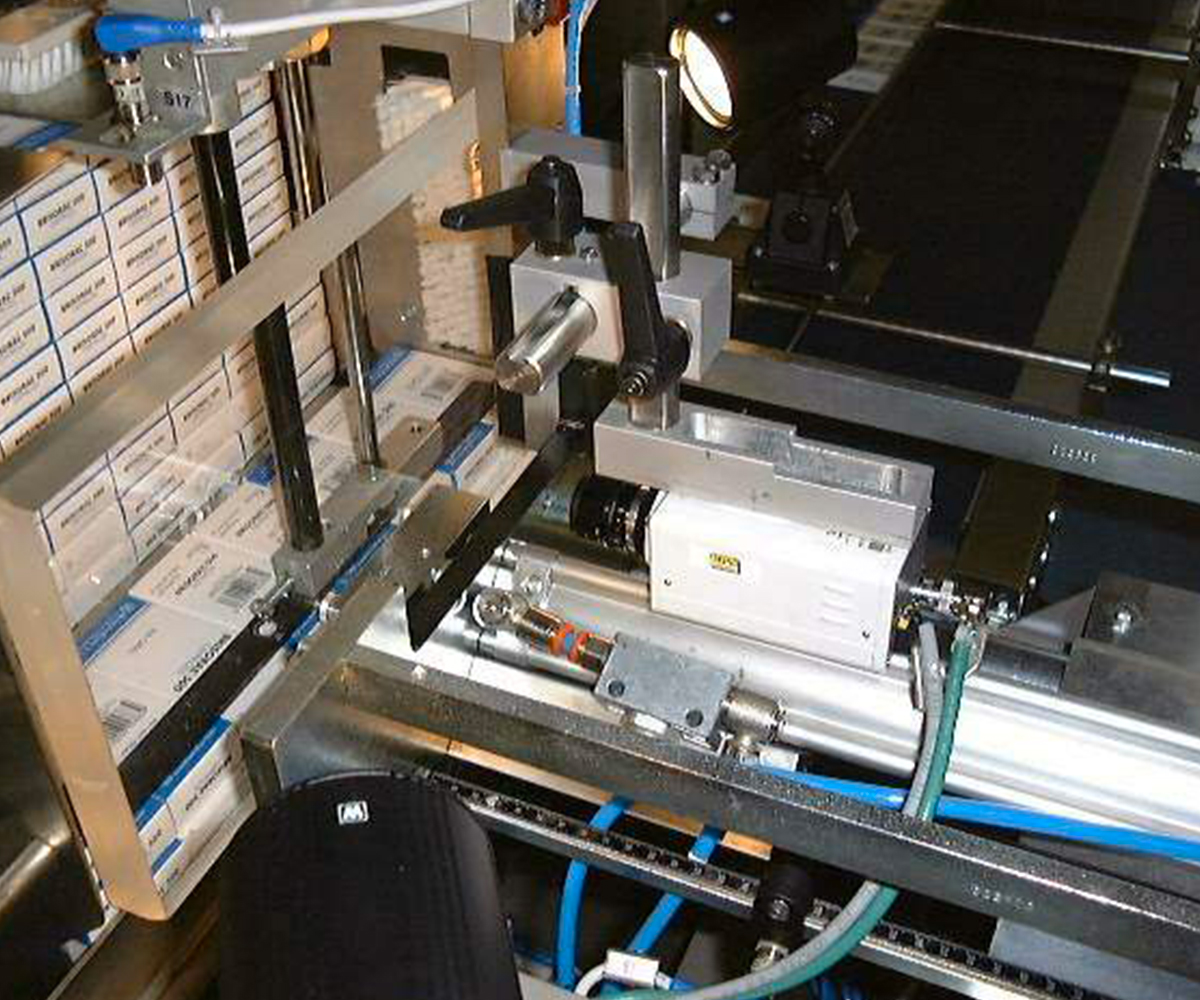

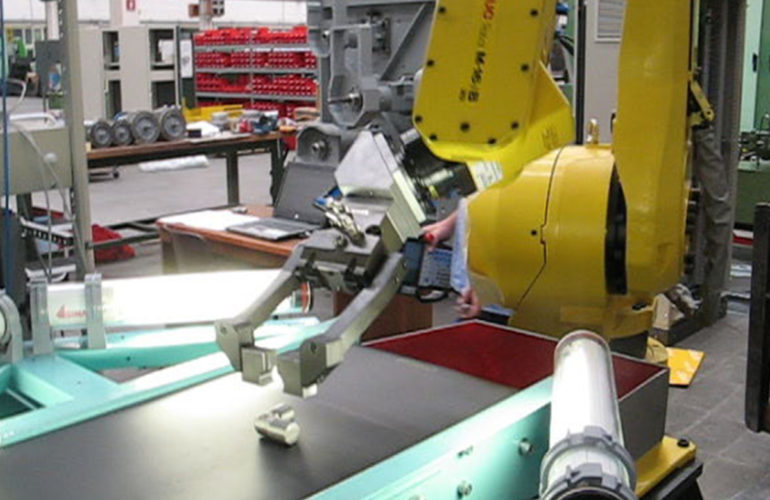

Specialvideo has realized a vision system which, applied to the cartoning machines, allows to verify the cases presence in each carton layer before closing.

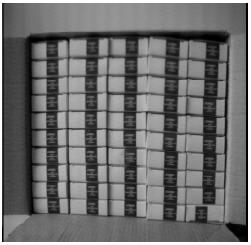

The vision system takes over and controls the image of the boxes staking at each layer, after the carton introduction. The control is done by comparison with a reference image recorded during the format development .The small normal variations in the boxes position are recognized and accepted, while the box lack or its abnormal position, generates an alarm. The layers control does not require pauses to the machine normal production cycle and also allows to check the very light boxes presence, which can escape to the normal control made with scales.

The system is insensitive to light variations, due to the inevitable components aging, thanks to special compensation algorithms.

The recording reference image for each thrust and the possibility to connect more cameras and variable light intensity adjustment of the, allow the vision system to adapt to the cartoning machines characteristics .

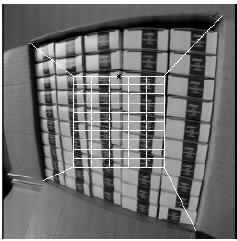

The control is carried out within the boxing machine, thus minimizes the overall dimensions. It is possible to place the camera in a different position with respect to the boxes frontal plane , so as not to change the pusher structure of the. For this reason it has been made a function software for image reconstruction (unwarping), which allows the correction of any image perspective deformation due to the camera angled position with respect to the box.

The recall of a previously stored format is obtained by PLC connected via input / output interface or directly from the keyboard.

It is also possible to certify the machine production storing the images of the boxes contents.