System functions

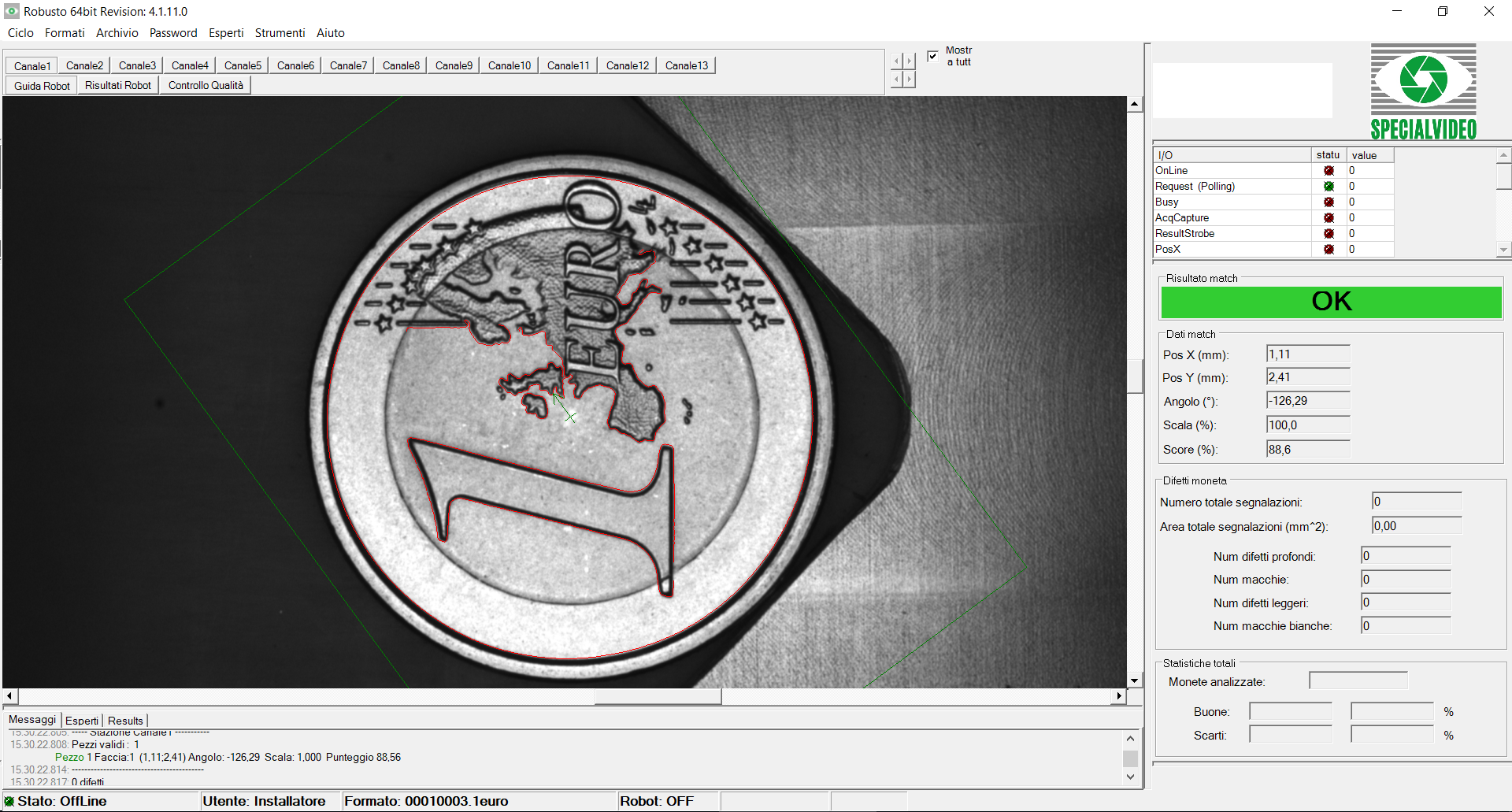

Specialvideo has created a system that characterizes the defects of the coins that have just come out of minting, based on the learning of the model coin and on the processing of the differences recognized as defects.

The vision system performs 100% quality control on the production line, with acquisition and processing time of less than 1 second per coin, and allows to guarantee, unlike human visual inspection, objectivity, reliability and consistency over time.

The system has been sized to check not only coins but also medals up to 40mm in diameter.

Performed checks

The main controls performed by the system are:

Realization

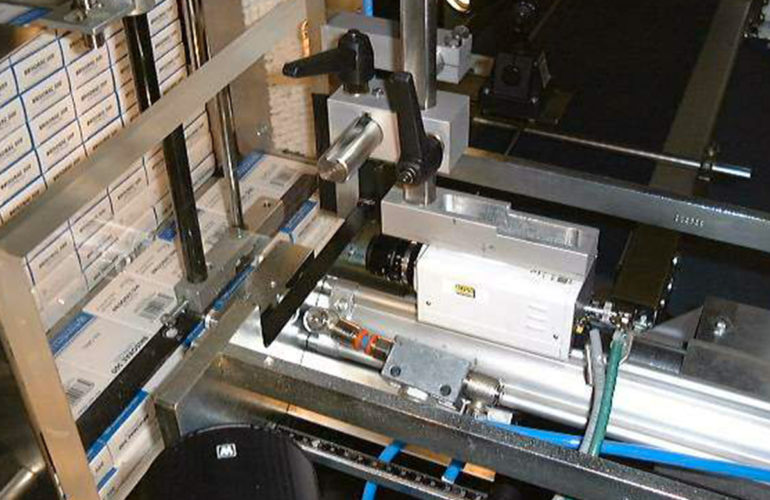

The vision system is integrated into the customer’s robotic island which makes the Brilliant Uncirculated pass through two groups of six channels, before being packaged in blisters.

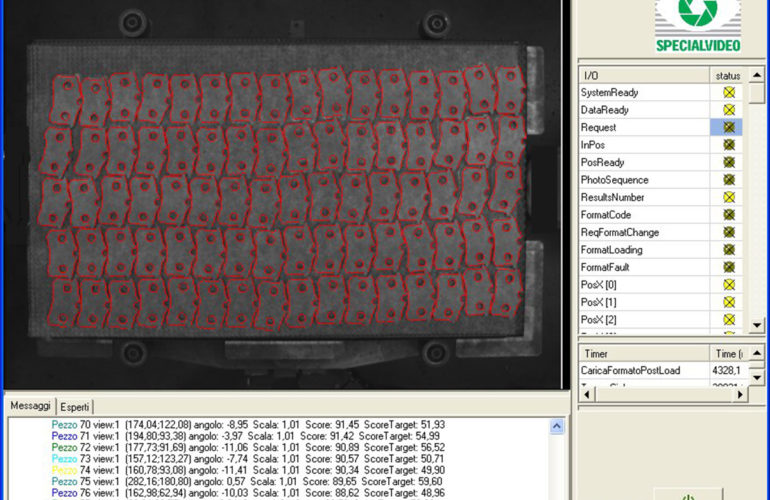

The coins arrive singularly in each channel and, thanks to a final “V” invitation, are brought as far as possible towards the center of the same. The angular orientation and the exposed “heads/tails” face are random.

For each of the two groups of channels we have:

- a robot that takes care of picking up the coins and depositing them oriented in the blisters;

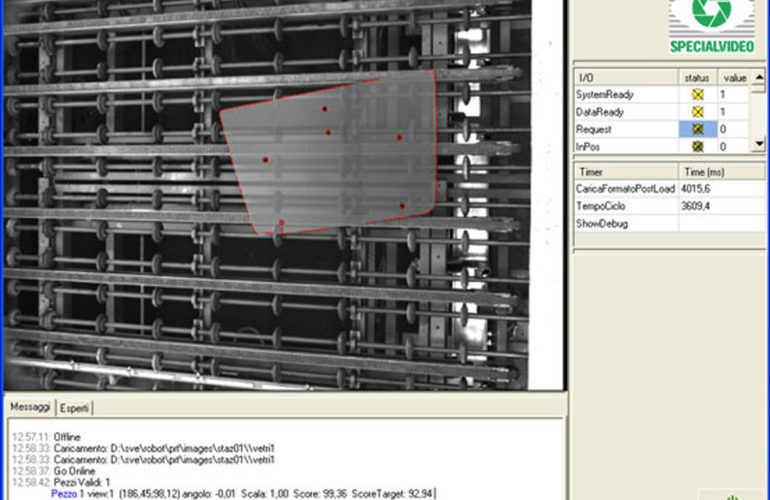

- a controlled axis thanks to which a camera is moved over each of the 6 channels;

- a tipper that turns the coin over if the exposed face is not the desired one

A third camera is fixed in the path between the channels and the blisters to check the back of the coin.

The vision system, therefore, consists of two twin systems capable of communicating with the PLC/Robot and capable of simultaneously managing two control stations. The modularity of the software allows you to choose whether to coordinate the stations on a single PC or on several PCs in the case of production lines that require an increase in response speed.

The vision software is able to:

- locate the coin in the image and estimate its x, y and angle coordinates;

- recognize the exposed face head/tails;

- control the quality of the surface of the coin, comparing it with the previously memorized model coin;

- communicate the coordinates of the coin and the outcome of the quality control to the PLC/Robot;

- graphically display defects, insert them in statistics and archive them on disk together with the corresponding photos.

Lighting

The most suitable lighting for highlighting the surface irregularities, spots and halos, was studied by Specialvideo technicians during the preliminary study in the laboratory, comparing different illuminators and selecting the most effective solution for the characteristics of the coined product.

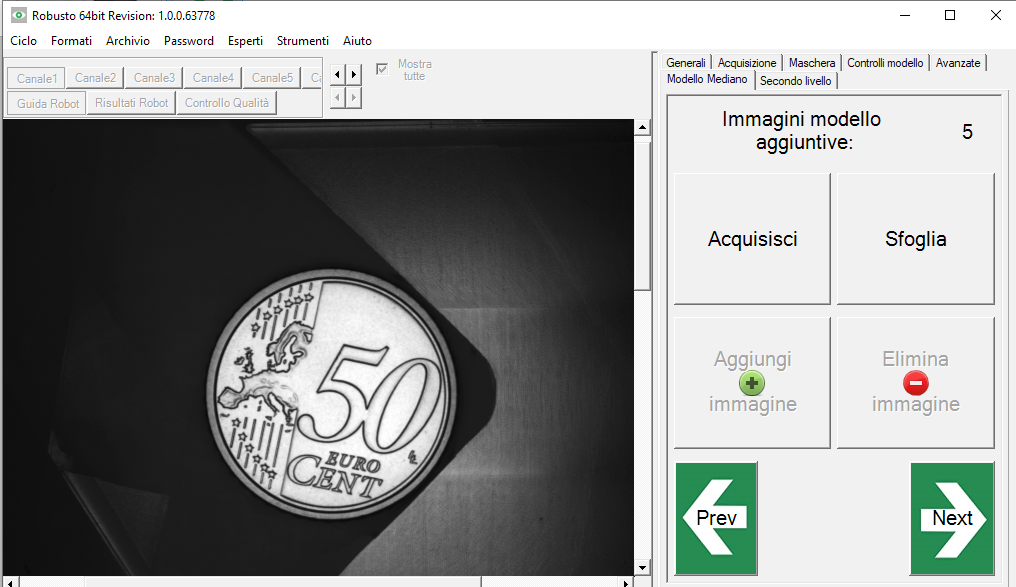

The model coin

The concept of compliant currency is learned by the system by memorizing a series of coins free from gross defects or in any case having defects at different points of the coin. From that series, the system elaborates the model coin, therefore it takes into account the acceptable variability, due to the production process. Then the system detects the possible defects through specific algorithms for comparison with the model.

Once the new format has been learned, it is permanently saved on the computer and associated with a mnemonic code. The recall of a previously stored format can be done either automatically by the PLC or manually.

After the format learning phase, the user with the appropriate password has the parameters to increase or decrease the selectivity of the system according to production needs.