System functions

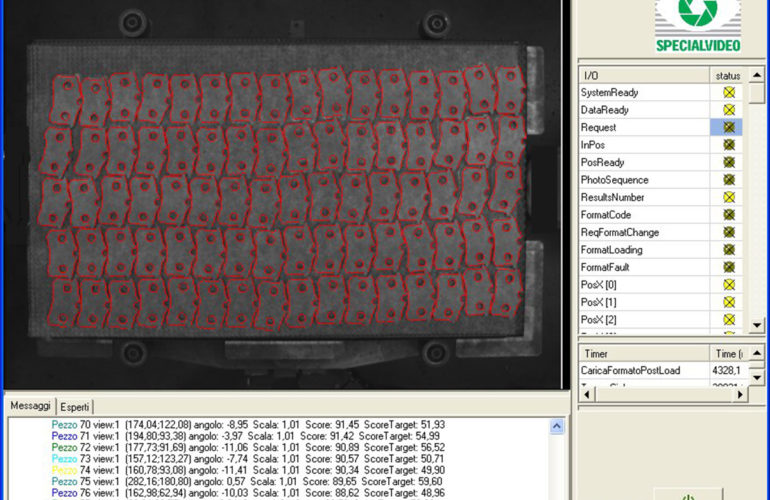

To ensure that the tarts are good as well as beautiful, Specialvideo has developed a vision system able to interpret the tarts appearance , deliberately never identical to each other, to discard those too irregular.

The vision system performs quality control up to 100% of the production line, upstream of packaging in flow-pack, with a maximum frequency of 12000 pcs / h, and allows to guarantee, unlike human visual inspection , objectivity, reliability, and consistency over time of the control.

Performed checks

The main controls performed by the system are:

Realization

The system has been implemented in order to take into account the production homogeneity lack, variations toleration due to the”rustic” aspect and irregularities discard that make the product unappealing to the consumer eye .

The control complex consists in checking the internal grid. completeness and correctness .

By the production process nature, the tarts are never perfectly identical to each other, and the “regularity” concept has to be translated in this case with a judgment on the product “beauty”, difficult concept to implement in a machine. For this purpose have been made special software algorithms able to assess the product regularity, and then the product beauty.

In addition to the internal grid regularity , the system checks the correct tart cooking level and check that there are no dough scraps on jam, jam tracks on the dough edge, black points or foreign bodies.

If the tart analyzed does not meet the quality specifications, the vision system activates the appropriate expulsion device with two different scrap procedures depending on the defect type. The total jam lack or not intact tarts are considered for use as livestock waste, while all other defects classify the product as a second choice.

Lighting

The lighting devices design and the optics to be used is one of the most important steps in the vision system realization because in order to obtain a good image is essential to build a good system.

In this case, the hue of fresh apricot jam is pretty much the same as the pasta. It has been necessary to design and build a particular lighting system, equipped with appropriate filters, to highlight the dough strips from the jam and to avoid the reflexes typical of some jam types.

New formats self-learning

One of the most stringent production systems requirements is the flexibility, which requires the quick line adaptability to different products in constant evolution.

The vision system

The new product introduction is via a self-learning procedure where is sufficient that the operator, during this phase, controls the first products analyzed that are not defective.

The vision system learns about the new parameters that must be checked and the acceptability new product limits.

In particular, the drive system learns about the good tarts central area geometric characteristicsand it builds a data base of statistical data based on the products analyzed during the self-learning step.

Once learned the new format, it is saved permanently on the computer and associated to a mnemonic code. The past stored format recall can be done automatically by the PLC via digital I / O or manually from the keyboard.

After the self-learning step, the user provided with password has available a parameter to increase or decrease the system selectivity according to the production needs.