System functions

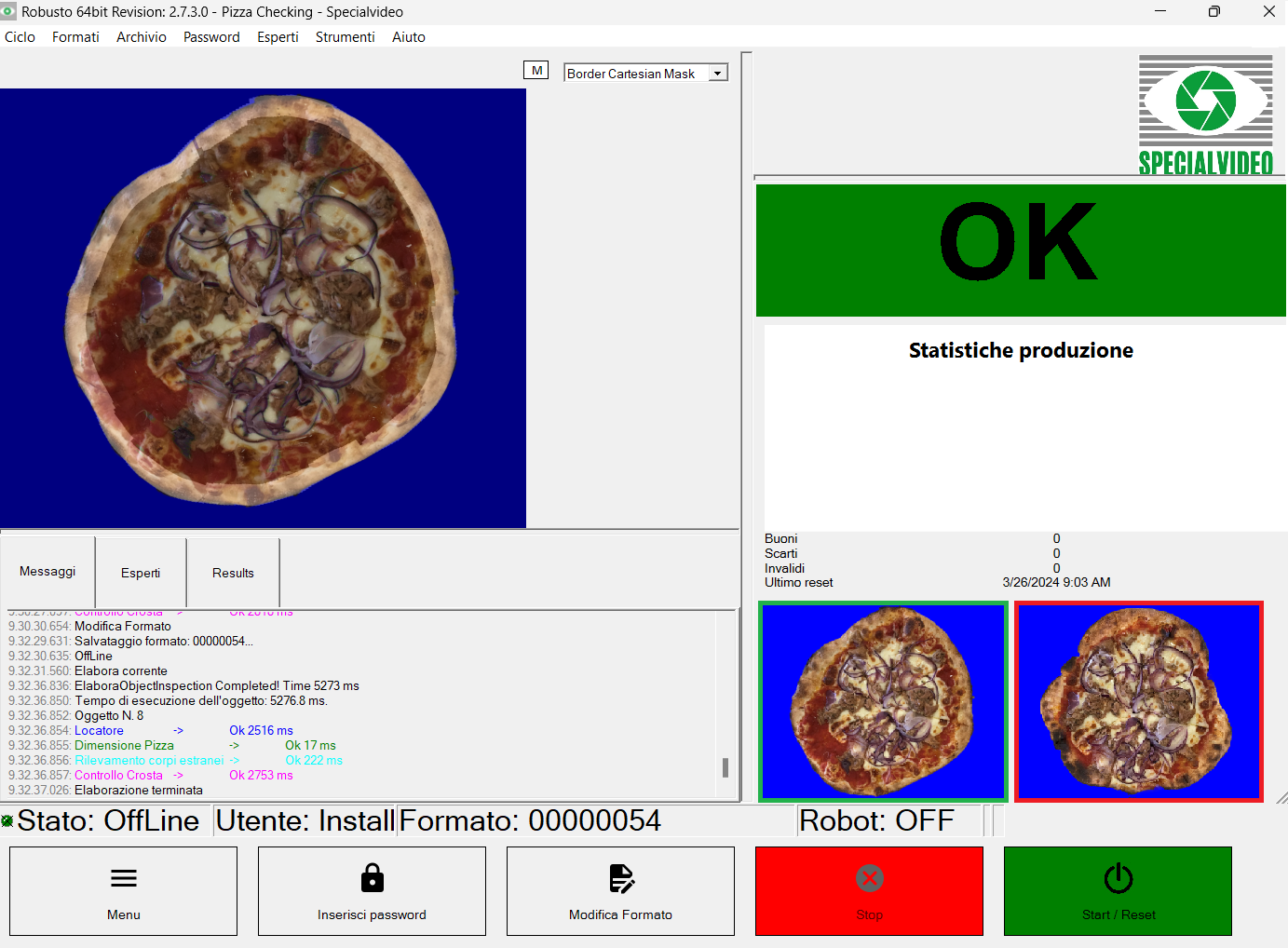

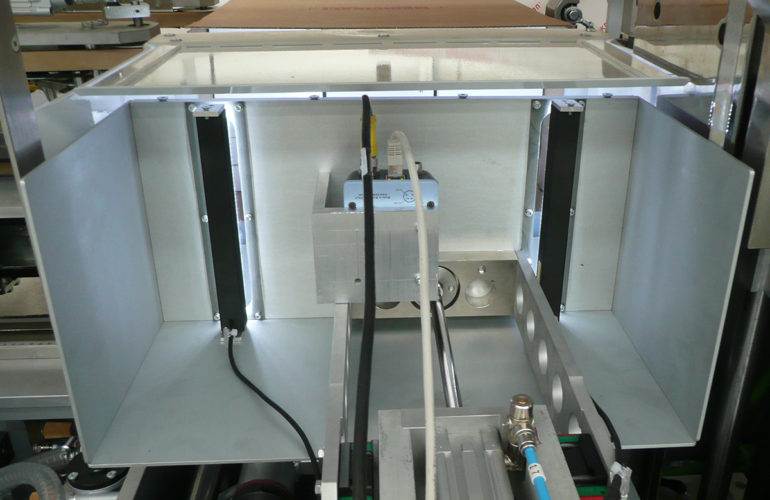

The vision system for quality control of pizzas inspects the toppings by returning the count and extent of ingredients classified by type, as well as performing classic checks such as shape integrity, color conformity, and detection of possible blue pollutants.

The application made for pizzas is suitable for other food products that have the ingredients to be checked visibly arranged, e.g., ready-made salad and pasta dishes.

The shape and color inspections are carried out with classical computer vision, while the detection and counting of toppings is done by neural networks.

Classical shape and color inspection

The main classical inspections performed by the system are:

Recognition of topping ingredients using deep learning

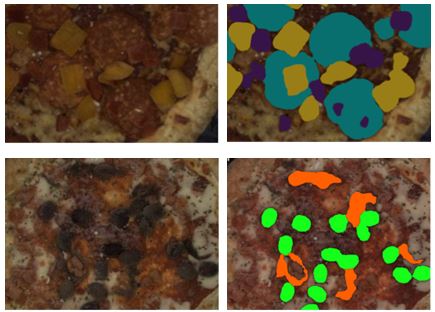

The system makes it easy to identify the topping ingredients on the pizza thanks to a state-of-the-art neural network that can be trained from just 20 images. The accurate identification of the products then allows for easier follow-up checks, whether it is the counting of ingredients, their spatial distribution, or even the control of topping colors.

Thanks to Artificial Intelligence, the system is extremely versatile and flexible, allowing with a single solution to identify very different items, but at the same time avoiding false positives such as recognizing a burn on the ledge as an olive.

The system in question was trained with several hundred pizzas for each recipe, and the network was able to learn how to distinguish the various ingredients: note the identification of red peppers on top of salami that was also red, and the accuracy with which the network follows the perimeter of anchovies!

The neural network succeeds in the task of identifying and counting ingredients even when they are partially occluded or overlapping.

Application for pizzas of various shapes and sizes

We tested our system in ingredient recognition on products different from the initial ones, obtaining surprising results.

Taking a pizza generated by ChatGPT 4.0, our system succeeded in the feat of recognizing all the olives on the pizza without ever having seen similar pizzas to that one, demonstrating that the network has learned the visual semantics of the olive. This allows us to offer customers quick adaptations of the system to product variations.

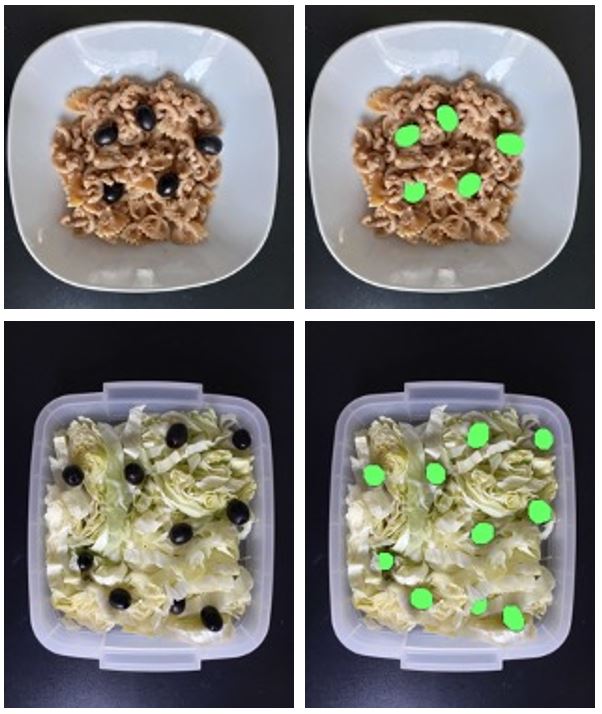

Application to other food products

A promising result regarding the extension of our control system was the recognition of ingredients even on food products never used during the training such as salad and pasta. This gives us a great advantage on new products with common characteristics to the products already seen and the process of dataset construction will be greatly speeded up. For example, we obtained recognition on salad and pasta of various ingredients learned in the context of topped pizzas.